Welcome to the world of manufacturing and distribution ERP solutions! If you’re looking to streamline your operations, improve efficiency, and maximize profitability, you’ve come to the right place. ERP software is designed to help businesses in the manufacturing and distribution industry manage their processes more effectively, from production planning to inventory management to supply chain optimization. With the right ERP solution, you can take your business to the next level and stay ahead of the competition.

Overview of Manufacturing ERP Solutions

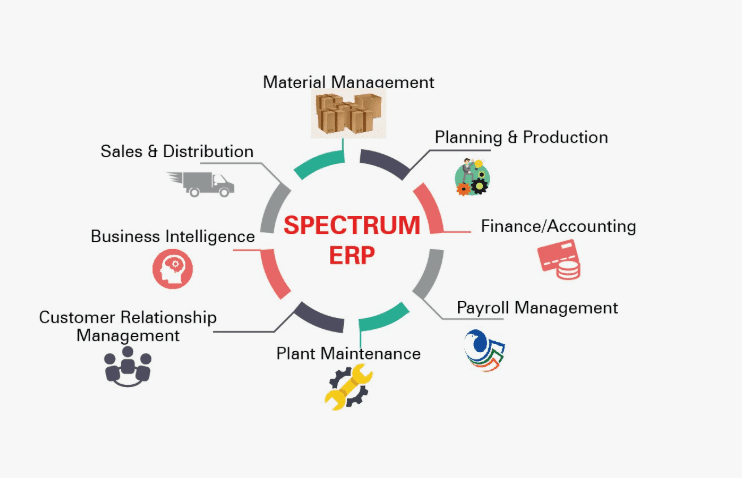

Manufacturing ERP solutions are a type of software specifically designed to streamline and optimize the processes involved in manufacturing and distribution. These solutions are tailored to meet the unique needs of manufacturers, helping them manage everything from production to inventory to customer orders. By integrating various functions into a single system, manufacturing ERP solutions help businesses improve efficiency, reduce costs, and increase productivity.

One of the key features of manufacturing ERP solutions is their ability to centralize data and provide real-time visibility into all aspects of the manufacturing process. This means that managers can easily track production schedules, monitor inventory levels, and analyze sales data from one centralized dashboard. This level of visibility allows businesses to make informed decisions quickly and efficiently, helping them respond to changing market conditions and customer demands.

Another important aspect of manufacturing ERP solutions is their capacity to automate repetitive tasks and streamline workflows. By eliminating manual data entry and automating processes such as order processing, inventory management, and production scheduling, manufacturing ERP solutions help businesses save time and reduce errors. This not only improves operational efficiency but also ensures that orders are processed accurately and on time, leading to higher customer satisfaction.

Manufacturing ERP solutions also offer advanced reporting and analytics capabilities, allowing businesses to gain insights into their operations and performance. By analyzing key performance indicators and trends, businesses can identify opportunities for improvement, optimize their processes, and make informed strategic decisions. This data-driven approach helps businesses stay competitive in today’s fast-paced manufacturing industry.

Additionally, manufacturing ERP solutions often come with integrated customer relationship management (CRM) features, allowing businesses to manage customer interactions and sales processes more effectively. By consolidating customer information and communication channels into a single system, businesses can improve customer service, build stronger relationships, and drive sales growth. This holistic approach to managing customer relationships helps businesses maintain a strong competitive advantage in the market.

In conclusion, manufacturing ERP solutions play a vital role in helping businesses optimize their manufacturing and distribution processes. By providing real-time visibility, automating workflows, offering advanced analytics, and integrating CRM features, these solutions help businesses improve efficiency, reduce costs, and enhance customer satisfaction. With the right manufacturing ERP solution in place, businesses can stay competitive, adapt to changing market conditions, and drive growth in today’s dynamic manufacturing industry.

Key Features of Distribution ERP Solutions

Distribution ERP solutions are specifically designed to streamline the process of managing inventory, orders, and shipments in distribution businesses. These systems offer a wide range of features that can help companies improve efficiency, reduce costs, and increase customer satisfaction. Some of the key features of distribution ERP solutions include:

1. Inventory Management

One of the most important features of distribution ERP solutions is inventory management. These systems provide real-time visibility into inventory levels, allowing companies to track stock levels, location, and movement of goods. This helps businesses optimize inventory levels, reduce stockouts, and prevent overstocking. Additionally, distribution ERP solutions can automate inventory replenishment, generate reorder alerts, and support barcode scanning for accurate inventory tracking.

2. Order Management

Order management is another critical feature of distribution ERP solutions. These systems streamline the order processing workflow from order entry to fulfillment, ensuring timely delivery and customer satisfaction. Distribution ERP solutions can automate order entry, track order status in real-time, manage backorders, and support multiple sales channels such as online stores and sales representatives. This feature also includes the ability to generate invoices, shipping labels, and packing slips, as well as handle returns and exchanges.

3. Warehouse Management

Warehouse management is an essential component of distribution ERP solutions. These systems optimize warehouse operations by providing tools to manage picking, packing, and shipping processes efficiently. Distribution ERP solutions can optimize warehouse layout, automate picking routes, track inventory movement within the warehouse, and provide real-time visibility into warehouse operations. This feature also includes support for batch and serial number tracking, lot control, and integration with shipping carriers for seamless order fulfillment.

4. Supplier Management

Distribution ERP solutions also offer supplier management features to help companies collaborate with suppliers effectively. These systems provide tools to manage supplier information, track supplier performance, and negotiate pricing and terms. Distribution ERP solutions can automate purchase orders, streamline the procurement process, and support vendor portals for seamless communication with suppliers. This feature also includes the ability to track supplier lead times, manage supplier contracts, and analyze supplier performance to optimize sourcing decisions.

5. Reporting and Analytics

Reporting and analytics are essential features of distribution ERP solutions that provide insights into business performance and help companies make informed decisions. These systems offer customizable dashboards, pre-built reports, and ad-hoc query tools to analyze key performance indicators, track sales trends, and monitor inventory levels. Distribution ERP solutions can generate financial reports, sales reports, and inventory reports, as well as provide forecasts and demand planning tools to optimize inventory levels and reduce stockouts.

In conclusion, distribution ERP solutions offer a comprehensive set of features to help distribution businesses manage inventory, orders, and shipments effectively. These systems can improve operational efficiency, reduce costs, and enhance customer satisfaction by streamlining business processes and providing real-time visibility into operations. By implementing a distribution ERP solution, companies can gain a competitive edge in the fast-paced distribution industry.

Benefits of Implementing an ERP System in Manufacturing

Implementing an ERP system in manufacturing can have a multitude of benefits for companies looking to streamline their operations and increase efficiency. From improved inventory management to better production planning, there are many advantages to using an ERP system in the manufacturing industry.

One of the key benefits of implementing an ERP system in manufacturing is better inventory management. With an ERP system, companies can track their inventory in real-time, allowing them to better monitor stock levels and avoid over or understocking. This can lead to reduced storage costs and improved cash flow, as companies are able to more accurately predict their inventory needs.

Another benefit of using an ERP system in manufacturing is improved production planning. With an ERP system, companies can better plan their production schedules, taking into account factors such as machine availability, labor costs, and material availability. This can help companies to optimize their production processes and reduce lead times, ultimately leading to higher customer satisfaction and increased profits.

Additionally, implementing an ERP system in manufacturing can lead to better quality control. By using an ERP system to track production processes and monitor product quality, companies can identify and address issues more quickly, leading to a decrease in defective products and an increase in customer satisfaction. This can help companies to build a stronger reputation for quality and reliability in the market.

Furthermore, using an ERP system in manufacturing can also lead to cost savings. By streamlining processes and improving efficiency, companies can reduce their operating costs and increase their profitability. This can help companies to stay competitive in the market and position themselves for long-term success.

In conclusion, the benefits of implementing an ERP system in manufacturing are numerous and can have a significant impact on a company’s operations and bottom line. From improved inventory management to better production planning and cost savings, an ERP system can help companies to work smarter, not harder, and achieve their business goals more effectively.

Optimizing Production Processes with ERP Solutions

Manufacturing companies are constantly looking for ways to improve efficiency and reduce costs in their production processes. One way they can achieve this is by implementing ERP solutions. ERP, or Enterprise Resource Planning, systems are software applications that help businesses manage and integrate their core processes such as production, inventory management, and distribution.

One of the key benefits of using ERP solutions in manufacturing is the ability to optimize production processes. ERP systems provide real-time data and visibility into the production process, allowing businesses to make informed decisions and adjustments to improve efficiency and reduce waste. This real-time information helps companies identify bottlenecks in the production line, track work-in-progress inventory, and adjust production schedules to meet customer demand.

ERP solutions also help streamline production processes by automating repetitive tasks such as order processing, inventory management, and scheduling. By automating these processes, companies can reduce the risk of human error and improve overall accuracy and efficiency in their operations. This not only saves time and reduces costs but also improves the quality of products and services delivered to customers.

Furthermore, ERP solutions enable better communication and collaboration between different departments within a manufacturing company. By providing a centralized database of information and real-time updates on production status, ERP systems help break down silos between departments and improve coordination and efficiency across the organization. This integrated approach ensures that all departments are working towards common goals and objectives, leading to better decision-making and overall performance.

Another important aspect of optimizing production processes with ERP solutions is the ability to track and analyze key performance indicators (KPIs) in real-time. ERP systems provide customizable dashboards and reports that allow businesses to monitor and analyze production metrics such as cycle times, machine utilization, and production costs. By tracking these KPIs, companies can identify trends, set performance targets, and make data-driven decisions to continuously improve their production processes.

In conclusion, ERP solutions play a crucial role in helping manufacturing companies optimize their production processes. By providing real-time data, automating repetitive tasks, improving communication and collaboration, and tracking and analyzing key performance indicators, ERP systems help businesses improve efficiency, reduce costs, and deliver high-quality products and services to customers. Implementing an ERP solution is essential for companies looking to stay competitive in today’s fast-paced and dynamic manufacturing industry.

Challenges of Implementing ERP in Distribution Centers

Implementing an ERP system in distribution centers can be a complex and challenging process. There are several factors that contribute to the challenges faced by organizations when trying to implement ERP solutions. In this section, we will explore some of the main challenges and issues that companies encounter during the implementation of ERP in distribution centers.

One of the biggest challenges that companies face when implementing ERP in distribution centers is the high costs involved. ERP systems can be expensive to purchase, implement, and maintain. Companies have to invest a significant amount of money in purchasing the software, training their employees, and customizing the system to fit their specific needs. This can be a major financial burden for many organizations, especially small and medium-sized businesses.

Another challenge of implementing ERP in distribution centers is the complexity of the systems. ERP systems are designed to integrate and streamline all aspects of a company’s operations, including inventory management, order processing, and logistics. This complexity can make it difficult for employees to learn how to use the system effectively, leading to resistance and low adoption rates. Companies may also face challenges in customizing the system to meet their specific business processes and requirements.

Furthermore, companies may encounter challenges related to data migration when implementing ERP in distribution centers. Data migration involves transferring data from existing systems to the new ERP system, which can be a time-consuming and error-prone process. Companies may struggle to ensure the accuracy and completeness of the data during migration, leading to issues with data quality and reliability in the new system.

Additionally, implementing ERP in distribution centers may require changes to existing business processes and workflows. Companies may need to reengineer their processes to align with the capabilities of the ERP system, which can disrupt operations and lead to resistance from employees. This can result in delays and difficulties in achieving the expected benefits and improvements from the ERP system.

Finally, one of the key challenges of implementing ERP in distribution centers is the potential for system integration issues. ERP systems need to integrate seamlessly with other systems and technologies used by the company, such as warehouse management systems, supply chain management software, and e-commerce platforms. Ensuring smooth integration between these systems can be a complex and time-consuming process, requiring extensive testing and troubleshooting to resolve any compatibility issues.

In conclusion, implementing ERP in distribution centers presents significant challenges for companies, including high costs, system complexity, data migration issues, process changes, and system integration difficulties. Addressing these challenges requires careful planning, stakeholder engagement, and collaboration between business and IT teams to ensure a successful implementation and maximize the benefits of the ERP system.

Originally posted 2025-01-24 14:00:00.