Welcome to the world of inventory management system ERP! Whether you are a small business owner or a large enterprise, having an effective system in place to track and manage your inventory is crucial for success. An ERP system can streamline your operations, improve accuracy, and ultimately save you time and money. In this article, we will explore the benefits of implementing an inventory management system ERP and how it can help your business thrive in today’s competitive market.

Overview of Inventory Management Systems

Inventory management systems are software tools that help businesses keep track of their inventory levels, orders, sales, and deliveries. These systems are designed to streamline operations and improve efficiency by providing real-time updates on inventory levels and automating processes such as reordering and forecasting. In essence, inventory management systems help businesses manage their stock levels and ensure that they have the right amount of inventory on hand at all times to meet customer demand.

There are a variety of inventory management systems available on the market, ranging from simple spreadsheet-based solutions to complex enterprise resource planning (ERP) systems. Small businesses may find that a basic inventory management system is sufficient for their needs, while larger companies may require a more robust solution that integrates with other business functions such as accounting, sales, and purchasing.

One of the key benefits of using an inventory management system is that it can help businesses reduce costs and improve profitability. By having real-time visibility into inventory levels and sales data, companies can avoid stockouts, reduce excess inventory, and minimize carrying costs. Additionally, these systems can help businesses improve their inventory turnover rates by optimizing reorder points and lead times, resulting in better cash flow and higher profits.

Another advantage of inventory management systems is that they can improve customer satisfaction by ensuring that products are always available when needed. By accurately tracking inventory levels and sales trends, companies can avoid backorders and delays in delivery, which can lead to increased customer loyalty and repeat business. Additionally, by having the right products in stock at all times, businesses can capitalize on opportunities to upsell and cross-sell to customers, further driving revenue and growth.

Inventory management systems can also help businesses identify and mitigate risks related to inventory, such as theft, spoilage, and obsolescence. By tracking inventory movements and conducting regular audits, companies can detect discrepancies and address issues before they escalate. Additionally, these systems can provide insights into demand patterns and market trends, allowing businesses to make informed decisions about product assortments, pricing strategies, and promotional activities.

In conclusion, inventory management systems play a vital role in helping businesses maintain optimal stock levels, reduce costs, improve customer satisfaction, and mitigate risks. Whether a company is a small retailer or a multinational corporation, implementing an inventory management system can provide numerous benefits in terms of efficiency, profitability, and competitiveness in today’s fast-paced business environment.

Benefits of Implementing an ERP for Inventory Management

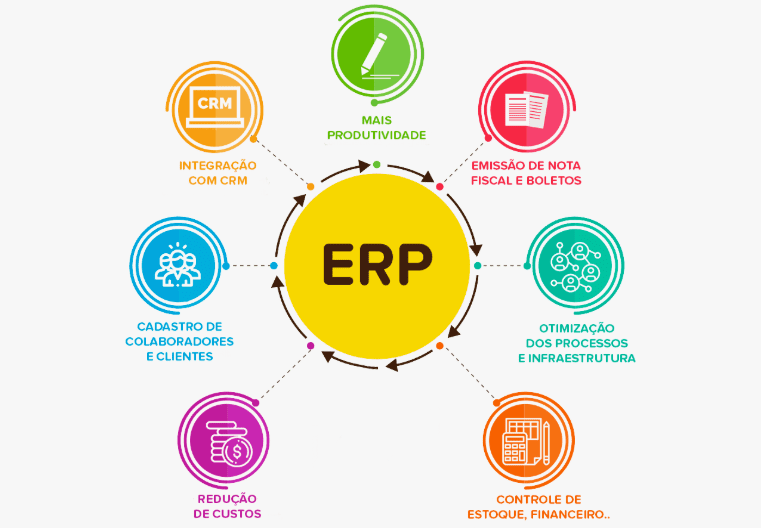

Implementing an Enterprise Resource Planning (ERP) system for inventory management can offer a multitude of benefits for businesses of all sizes. These benefits can range from increased efficiency and productivity to cost savings and improved decision-making processes. Let’s explore some of the key advantages of integrating an ERP system into your inventory management practices.

1. Improved Inventory Accuracy: One of the primary advantages of using an ERP system for inventory management is the ability to maintain accurate and up-to-date inventory levels. With real-time tracking and monitoring capabilities, businesses can easily track the movement of their inventory, identify any discrepancies or errors, and take proactive steps to address issues before they escalate. This can result in reduced stockouts, overstocking, and ultimately, improved customer satisfaction.

2. Enhanced Forecasting and Planning: Another significant benefit of implementing an ERP system for inventory management is the ability to enhance forecasting and planning processes. By analyzing historical data, current trends, and market demands, businesses can make more informed decisions about how much inventory to order, when to reorder, and where to allocate resources. This can help minimize excess inventory, optimize storage space, and ultimately, reduce costs associated with carrying obsolete or slow-moving stock.

3. Streamlined Operations: ERP systems are designed to streamline and automate various inventory management tasks, such as order processing, purchasing, and distribution. By integrating these processes into a centralized platform, businesses can eliminate manual data entry, minimize errors, and ensure seamless communication between different departments. This can result in faster order fulfillment, reduced lead times, and overall, a more efficient supply chain.

4. Cost Savings: Implementing an ERP system for inventory management can lead to significant cost savings for businesses. By optimizing inventory levels, reducing excess stock, and improving overall operational efficiency, businesses can minimize carrying costs, decrease storage expenses, and ultimately, enhance their bottom line. Additionally, by enhancing visibility and control over inventory, businesses can better negotiate with suppliers, identify cost-saving opportunities, and improve overall financial performance.

5. Improved Decision-Making: Lastly, ERP systems can provide businesses with valuable insights and analytics that can help improve decision-making processes. By analyzing key performance indicators, such as inventory turnover, stock levels, and order fulfillment rates, businesses can make data-driven decisions about inventory management strategies, resource allocation, and future growth opportunities. This can lead to better strategic planning, improved operational performance, and ultimately, a competitive advantage in the marketplace.

In conclusion, implementing an ERP system for inventory management can offer a wide range of benefits for businesses looking to enhance efficiency, reduce costs, and improve overall operational performance. By leveraging advanced technology, automation, and data analytics, businesses can streamline inventory management processes, improve inventory accuracy, and ultimately, drive growth and profitability in the long run.

Features to Look for in an Inventory Management System ERP

When choosing an Inventory Management System ERP for your business, there are several key features that you should look out for to ensure that it meets your needs and requirements. Here are some features to consider:

1. Integration with other systems: A good inventory management system ERP should be able to seamlessly integrate with other systems that your business uses, such as accounting software, CRM systems, and e-commerce platforms. This integration ensures that data can flow smoothly between different systems, reducing the need for manual data entry and minimizing errors.

2. Real-time inventory tracking: One of the main advantages of using an inventory management system ERP is the ability to track your inventory in real-time. This means that you can see exactly how much stock you have on hand, what is on order, and when you need to reorder items. Look for a system that provides accurate and up-to-date information on your inventory levels to help you make informed decisions.

3. Advanced reporting and analytics: In addition to tracking your inventory, a good inventory management system ERP should also provide advanced reporting and analytics features. These features allow you to analyze trends, identify areas for improvement, and make data-driven decisions to optimize your inventory management processes. Look for a system that offers customizable reports, dashboards, and key performance indicators (KPIs) that are tailored to your business needs.

4. Inventory optimization tools: Another important feature to look for in an inventory management system ERP is inventory optimization tools. These tools help you minimize stockouts, reduce excess inventory, and improve overall inventory turnover. Look for features such as demand forecasting, automatic reorder points, and economic order quantity (EOQ) calculations to help you optimize your inventory levels and ensure that you always have the right amount of stock on hand.

5. Multi-location support: If your business operates in multiple locations, it’s important to choose an inventory management system ERP that supports multi-location inventory tracking. This feature allows you to manage inventory levels across different warehouses, stores, or production facilities, ensuring that stock is distributed efficiently and accurately.

By considering these key features when choosing an inventory management system ERP, you can select a system that meets your business needs and helps you streamline your inventory management processes. With the right system in place, you can improve efficiency, reduce costs, and optimize your inventory levels for better business outcomes.

Steps to Successfully Implement an Inventory Management System ERP

Implementing an Inventory Management System ERP can be a daunting task, but with the right approach, it can be a smooth and successful process. Here are the steps to successfully implement an Inventory Management System ERP:

1. Define your goals and objectives

The first step in implementing an Inventory Management System ERP is to clearly define your goals and objectives. What are you hoping to achieve with the system? Whether it’s reducing inventory costs, streamlining processes, or improving accuracy, having clear objectives will guide the implementation process.

2. Select the right system for your business

Choosing the right Inventory Management System ERP for your business is crucial for a successful implementation. Consider factors such as the size of your business, industry-specific requirements, and scalability. It’s essential to choose a system that aligns with your goals and objectives.

3. Plan the implementation process

Once you have selected a system, it’s time to plan the implementation process. This involves mapping out the steps involved, setting timelines, assigning responsibilities, and allocating resources. A well-thought-out implementation plan will help ensure a smooth transition to the new system.

4. Train your staff

Training your staff is a critical component of implementing an Inventory Management System ERP. Your employees need to be familiar with the new system and understand how to use it effectively. Providing comprehensive training sessions, hands-on workshops, and ongoing support will help ensure a successful implementation.

Training should be tailored to the specific roles and responsibilities of each employee. For example, warehouse staff may need training on scanning and picking processes, while managers may require training on reporting and analytics. Offering different levels of training based on job function will ensure that all employees are equipped to use the system efficiently.

It’s also essential to provide ongoing support and resources for your staff as they navigate the new system. This could include access to user manuals, online tutorials, and a helpdesk for troubleshooting. Encouraging an open line of communication and feedback will help address any issues or concerns that arise during the implementation process.

5. Test the system

Before fully implementing the Inventory Management System ERP, it’s essential to test the system thoroughly. This involves running simulations, conducting test transactions, and troubleshooting any potential issues. Testing will help identify any bugs or errors and ensure that the system meets your requirements before going live.

6. Go live and monitor performance

Once you have completed training, testing, and preparation, it’s time to go live with the Inventory Management System ERP. Monitor the system’s performance closely in the initial stages to identify any issues and make adjustments as needed. Regular monitoring and evaluation will help ensure that the system continues to meet your goals and objectives over time.

By following these steps and taking a strategic approach to implementation, you can successfully integrate an Inventory Management System ERP into your business and reap the benefits of improved efficiency, accuracy, and cost savings.

Case Studies of Companies Using Inventory Management System ERPs

Inventory Management System ERPs have become an essential tool for businesses looking to streamline their operations and improve efficiency. Many companies across various industries have successfully implemented these systems to gain better control over their inventory levels, reduce costs, and enhance their overall business performance. Here are some case studies of companies that have leveraged Inventory Management System ERPs to achieve success:

1. Company X: Company X is a leading retail company that specializes in selling electronic gadgets. With a wide range of products and multiple store locations, they were facing challenges in managing their inventory effectively. By implementing an Inventory Management System ERP, Company X was able to centralize their inventory data, track stock levels in real-time, and automate the reordering process. This led to a significant reduction in stockouts, improved customer satisfaction, and increased sales.

2. Company Y: Company Y is a manufacturing company that produces automotive parts for various clients. With a complex supply chain and multiple production facilities, they were struggling to keep track of their inventory levels and production schedules. By adopting an Inventory Management System ERP, Company Y was able to optimize their production processes, reduce lead times, and improve inventory accuracy. This resulted in a 20% increase in production efficiency and a 15% decrease in inventory holding costs.

3. Company Z: Company Z is a distribution company that supplies medical equipment to healthcare providers across the country. With a large inventory of perishable items and strict regulatory requirements, they needed a robust system to manage their inventory effectively. By integrating an Inventory Management System ERP with their existing software, Company Z was able to streamline their order processing, track expiration dates, and improve inventory visibility. This enabled them to reduce product waste, avoid stock obsolescence, and comply with industry regulations.

4. Company A: Company A is a food and beverage company that operates multiple restaurants in different locations. With a diverse menu and fluctuating customer demand, they were facing challenges in managing their inventory levels and controlling costs. By implementing an Inventory Management System ERP, Company A was able to optimize their menu planning, track ingredient usage, and monitor supplier performance. This led to a 10% reduction in food waste, a 25% decrease in procurement costs, and a 30% increase in overall profitability.

5. Company B: Company B is a global e-commerce company that sells a wide range of products online. With a high volume of orders and a complex network of suppliers, they needed a reliable system to manage their inventory efficiently. By investing in an Inventory Management System ERP, Company B was able to automate their order fulfillment process, track inventory movements across their warehouses, and improve order accuracy. This resulted in a 50% reduction in order processing time, a 40% increase in on-time deliveries, and a 20% decrease in fulfillment costs.