Welcome to the world of inventory management ERP systems, where organization meets efficiency in the most seamless way possible. These systems are designed to streamline the process of tracking, managing, and organizing inventory for businesses of all sizes. Imagine a tool that not only keeps track of your products but also provides valuable insights into your supply chain and helps you make informed decisions. With inventory management ERP systems, the possibilities are endless and the benefits are invaluable.

Overview of Inventory Management ERP Systems

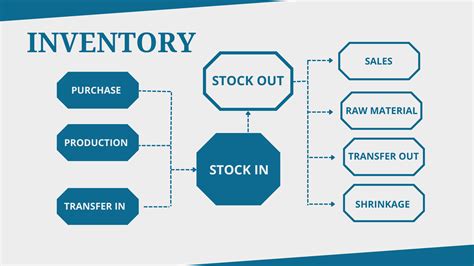

Inventory management ERP systems serve as a comprehensive tool for businesses to efficiently track, manage, and optimize their inventory levels. These systems integrate various functions such as inventory control, purchasing, order fulfillment, and production planning into a single platform, providing real-time visibility and control over the entire supply chain.

One of the key features of inventory management ERP systems is their ability to automate inventory tracking processes. By centralizing inventory data and automating tasks such as barcode scanning, stock counting, and replenishment notifications, businesses can significantly reduce the risk of human error and ensure accurate inventory levels at all times. This not only helps in preventing stockouts or overstock situations but also streamlines the overall inventory management process.

Moreover, inventory management ERP systems offer advanced forecasting and demand planning capabilities, enabling businesses to anticipate future inventory needs based on historical data, market trends, and customer demand patterns. By generating accurate demand forecasts and optimizing inventory levels accordingly, businesses can minimize excess inventory costs, improve order fulfillment rates, and enhance customer satisfaction.

Another benefit of inventory management ERP systems is their ability to streamline procurement processes. By connecting inventory data with supplier information and purchase orders, businesses can automate the procurement workflow, track supplier performance, and negotiate better terms with vendors. This not only helps in reducing procurement lead times but also ensures that businesses have the right amount of inventory on hand to meet customer demand.

Furthermore, inventory management ERP systems provide real-time visibility into key performance indicators (KPIs) such as inventory turnover rate, fill rate, and carrying costs. By generating customizable reports and dashboards, businesses can gain actionable insights into their inventory performance, identify inefficiencies or bottlenecks in the supply chain, and make informed decisions to optimize inventory management processes.

In conclusion, inventory management ERP systems play a crucial role in helping businesses streamline their inventory management processes, optimize inventory levels, and improve overall supply chain efficiency. By leveraging advanced features such as automation, forecasting, and procurement optimization, businesses can enhance inventory accuracy, reduce operational costs, and drive business growth in the competitive marketplace.

Benefits of Implementing an ERP System for Inventory Management

Implementing an ERP system for inventory management can bring a multitude of benefits to your business. From streamlining processes to maximizing efficiency, here are some of the key advantages of using an ERP system for inventory management:

1. Improved Accuracy and Timeliness: With an ERP system in place, manual data entry errors are significantly reduced, leading to more accurate inventory records. This helps in preventing stockouts and overstock situations, ultimately improving customer satisfaction and reducing carrying costs. Additionally, real-time data updates ensure that information is always up-to-date, allowing for better decision-making and planning.

2. Enhanced Visibility and Control: One of the major benefits of implementing an ERP system for inventory management is the enhanced visibility it provides into your supply chain. With features such as real-time tracking of inventory levels, orders, and shipments, you can gain better control over your inventory and monitor stock movements more effectively. This visibility not only helps in minimizing stockouts and overstock situations but also enables you to optimize reorder points and reduce lead times. Moreover, having a centralized system for inventory management allows for better coordination between different departments, leading to improved communication and collaboration.

3. Increased Efficiency and Productivity: By automating various inventory management tasks such as order processing, replenishment, and forecasting, an ERP system helps in saving time and reducing the need for manual intervention. This, in turn, increases efficiency and productivity within the organization, allowing employees to focus on more strategic activities. Additionally, with features like automated workflows and alerts, potential issues can be identified and resolved proactively, preventing costly disruptions in the supply chain.

4. Cost Savings: Implementing an ERP system for inventory management can lead to substantial cost savings for your business. By optimizing inventory levels, reducing carrying costs, and minimizing stockouts, you can lower operating expenses and improve overall profitability. Furthermore, by streamlining processes and improving efficiency, you can save on labor costs and reduce the likelihood of costly errors.

5. Scalability and Flexibility: An ERP system is designed to grow with your business, making it highly scalable and adaptable to changing needs. Whether you are expanding into new markets, adding new product lines, or increasing your customer base, an ERP system can easily accommodate these changes and help you maintain a competitive edge in the market. Additionally, with customizable features and modules, you can tailor the system to suit your specific requirements and ensure that it aligns with your organizational goals.

In conclusion, the benefits of implementing an ERP system for inventory management are numerous and can have a significant impact on your business operations. From improved accuracy and visibility to increased efficiency and cost savings, an ERP system can help you streamline processes, optimize inventory levels, and stay ahead of the competition. By investing in an ERP system for inventory management, you can take your business to the next level and achieve long-term success.

Key Features of Inventory Management ERP Systems

Inventory management ERP systems play a crucial role in helping businesses manage their inventory efficiently. These systems come equipped with a variety of features that make it easier for businesses to track, organize, and optimize their inventory levels. Some key features of inventory management ERP systems include:

1. Real-time Inventory Tracking: One of the most important features of inventory management ERP systems is real-time inventory tracking. This feature allows businesses to monitor their inventory levels at any given time, providing them with up-to-date information on what they have in stock, what needs to be ordered, and what is selling well. By having real-time visibility into their inventory, businesses can make better purchasing decisions and avoid stockouts or overstocking.

2. Inventory Optimization Tools: Another key feature of inventory management ERP systems is inventory optimization tools. These tools use algorithms and data analysis to help businesses determine the optimal levels of inventory to keep on hand. By taking into account factors such as demand forecasts, lead times, and carrying costs, these tools can help businesses minimize excess inventory while ensuring that they have enough stock to meet customer demand.

3. Demand Forecasting and Planning: Demand forecasting and planning are essential components of inventory management ERP systems. These features use historical sales data, market trends, and other factors to predict future demand for products. By accurately forecasting demand, businesses can better plan their inventory levels, production schedules, and purchasing decisions. This can help businesses reduce inventory holding costs, improve customer service levels, and increase overall efficiency.

4. Multi-location Inventory Management: Many businesses operate out of multiple locations or warehouses, making it essential to have a feature that can manage inventory across different locations. Inventory management ERP systems with multi-location support allow businesses to track inventory levels at each location, transfer stock between locations, and fulfill orders from the nearest warehouse. This feature helps businesses avoid stockouts, reduce shipping costs, and improve overall inventory visibility.

5. Batch and Serial Number Tracking: For businesses that deal with products that have batch or serial numbers, inventory management ERP systems often include features for tracking these numbers. This allows businesses to trace products back to their origins, identify defects or recalls, and maintain accurate records for compliance purposes. Batch and serial number tracking can help businesses improve quality control, manage recalls more efficiently, and ensure product traceability.

6. Integration with Other Business Processes: To truly optimize inventory management, ERP systems should be able to integrate seamlessly with other business processes such as accounting, sales, and supply chain management. Integration allows for data sharing across departments, streamlines workflows, reduces errors, and provides a holistic view of the business. By having all systems interconnected, businesses can make more informed decisions and operate more efficiently.

Overall, inventory management ERP systems offer businesses a wide range of features to help them streamline their inventory processes, improve efficiency, and enhance customer service. By leveraging these key features, businesses can better manage their inventory, reduce costs, and ultimately drive growth and success.

Common Challenges and Solutions in Using ERP Systems for Inventory Management

Inventory management is a crucial aspect of any business, as it directly impacts the company’s bottom line. Many businesses rely on ERP systems to streamline their inventory processes and ensure accuracy in tracking their goods. However, using ERP systems for inventory management comes with its own set of challenges. Let’s explore some common challenges faced by businesses when using ERP systems for inventory management and the solutions to address them:

1. Data Accuracy:

One of the most common challenges businesses face when using ERP systems for inventory management is maintaining data accuracy. Inaccurate data can lead to overselling, stockouts, or incorrect financial reporting. To address this challenge, it is essential to regularly audit and cleanse data in the ERP system. Businesses should also invest in barcode scanning technology and automated data entry to minimize human errors.

2. Integration Issues:

Another challenge that businesses encounter is integrating their ERP system with other software applications such as CRM or e-commerce platforms. Lack of integration can lead to data silos and inefficiencies in inventory management. To overcome this challenge, businesses should look for ERP systems that offer seamless integration with other software applications. Additionally, they can consider using middleware or APIs to connect different systems and ensure data flow between them.

3. Scalability:

As businesses grow, they may face scalability challenges with their ERP systems for inventory management. The system may not be able to handle increased data volume or the complexity of the growing business operations. To address this challenge, businesses should regularly review their ERP system’s performance and scalability. They can consider upgrading to a more robust ERP solution or implementing cloud-based ERP systems that offer scalability and flexibility to adapt to changing business needs.

4. Training and Change Management:

One of the key challenges businesses face when implementing ERP systems for inventory management is training employees and managing change within the organization. Employees may resist using the new system, leading to low adoption rates and inefficiencies in inventory processes. To overcome this challenge, businesses should invest in comprehensive training programs for employees to familiarize them with the ERP system. They should also communicate the benefits of the new system and involve employees in the implementation process to gain their buy-in. Additionally, businesses can appoint super-users within the organization to provide ongoing support and training to other employees.

In conclusion, while using ERP systems for inventory management offers many benefits, businesses need to be aware of the common challenges they may face and proactively address them. By ensuring data accuracy, integrating systems, planning for scalability, and investing in training and change management, businesses can maximize the value of their ERP systems for efficient inventory management.

Case Studies on Successful Implementation of Inventory Management ERP Systems

Implementing an inventory management ERP system can be a game-changer for businesses looking to streamline their operations and improve efficiency. Here, we will discuss five case studies of successful implementation of inventory management ERP systems:

1. XYZ Company: XYZ Company, a manufacturing company, implemented an inventory management ERP system to keep track of their raw materials and finished goods. By using the system to automate their inventory control processes, they were able to reduce stockouts and overstock situations, leading to improved cash flow and increased customer satisfaction.

2. ABC Retail: ABC Retail, a chain of retail stores, integrated an inventory management ERP system to optimize their inventory levels and improve order fulfillment. With real-time visibility into their stock levels and sales data, they were able to make informed decisions on stock replenishment and reduce excess inventory, resulting in significant cost savings.

3. DEF Distribution: DEF Distribution, a distribution company, implemented an inventory management ERP system to streamline their warehouse operations and improve inventory accuracy. By using barcode scanning and automated replenishment processes, they were able to reduce manual errors and increase picking and packing efficiency, leading to faster order fulfillment and reduced lead times.

4. GHI Electronics: GHI Electronics, an electronics manufacturer, adopted an inventory management ERP system to track their inventory across multiple warehouses and production facilities. With the ability to manage their inventory levels centrally and automate stock transfers, they were able to improve inventory visibility and ensure optimal stock levels at all times, leading to improved production planning and on-time deliveries.

5. JKL Logistics: JKL Logistics, a logistics company, implemented an inventory management ERP system to optimize their supply chain processes and improve inventory visibility. By integrating their ERP system with their suppliers and customers, they were able to track inventory movements in real-time and improve order accuracy, leading to better collaboration and reduced lead times. Additionally, with the help of demand forecasting and inventory optimization tools, they were able to reduce excess inventory and improve inventory turnover rates.

Overall, these case studies demonstrate the benefits of implementing inventory management ERP systems in various industries. By streamlining inventory control processes, improving inventory visibility, and optimizing stock levels, businesses can achieve cost savings, improve operational efficiency, and enhance customer satisfaction.